Maintenance Safety

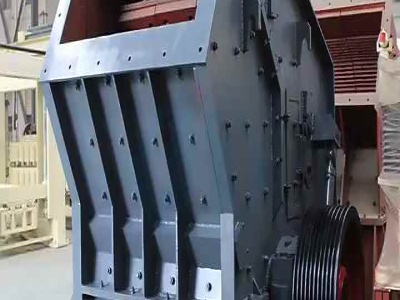

Grinder Hammer Tip Introduction. Proper maintenance safety programs are very important. Certain hazards associated with grinding machinery depend on many application specific details. Machine owners must develop utilize specific safety and maintenance programs to support their specific use of the machine at their job site.