Electrowinning 101: What is electrowinning?

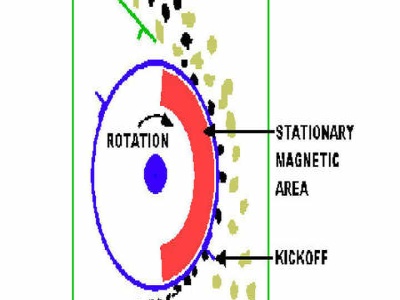

May 24, 2016· Another similar process is electrorefining which is strictly used in refining applications to improve the purity of the metals. Both processes use electroplating and are used to purify nonferrous metals such as copper and silver. A conventional electrowinning unit consists of a tank.