Rebel Crusher Mobile Jaw Crusher | Equipment Company

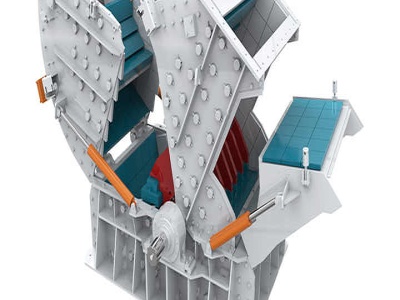

The REBEL CRUSHER has the ability to SWAP the TYPE of CRUSHER! That's right, you can swap from a JAW CRUSHER to an IMPACT CRUSHER or vice versa in a matter of hours. The same REBEL CRUSHER will operate either a jaw or an impact crusher! Prescreen and finish screen ensures QUALITY products are produced.