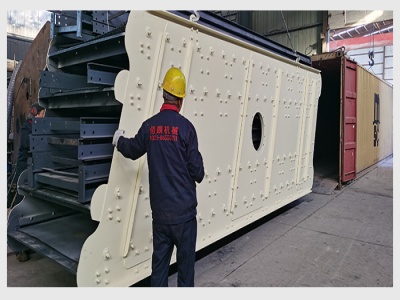

crushing and grinding of raw material in a cement in

cement raw material crushing and grinding indiacarezin. cement raw material crushing and grinding , Raw material preparation From the quarry to raw meal, cal production of highquality cements This can only be achieved . images of crushing of raw material to make cement.