Grinding | food processing |

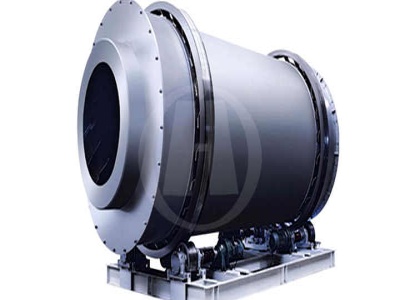

In cereal processing: Milling The first step in grinding for the gradual reduction process is performed between steel cylinders, with grooved surfaces, working at differential speeds. The wheat is directed between the first "break," or set of rolls, and is partially torn open.