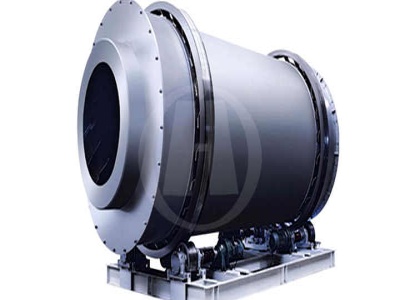

Autogenous and Semiautogenous mills Metso

Simplifying wet grinding with Metso AG/SAG mills AG/SAG mills are often the optimum solution for wet grinding (achieved in a slurry 50 to 80 percent solids). AG/SAG mills can accomplish the same size reduction work as two or stages of crushing and screening, a rod mill, and some or all of the work done by a ball mill.