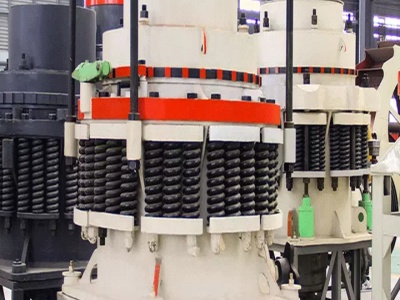

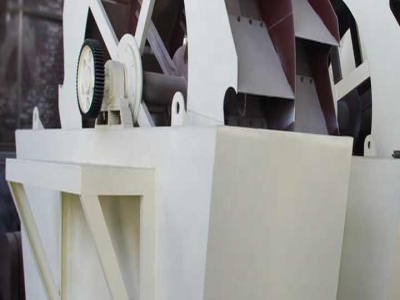

Cement Grinding Mineral Processing Metallurgy

RAW CEMENT GRINDING. This phase of grinding may be either the wet or dry process, the end product going to a kiln. Material ground consists of limestone, cement rock, marl or marine shells along with secondary materials usually shale or clay. A typical raw mix consists of 7585% limestone, 1225% shale, the balance consisting...