A Study on Strength and Durability Characteristics of ...

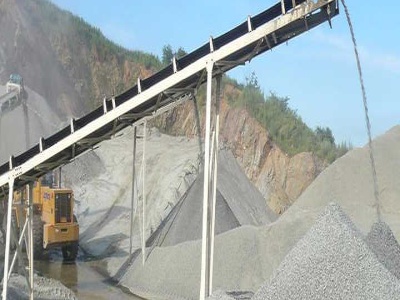

2) Aggregates ( Fine Coarse) The aggregate like sand, stone are inert materials. The behavior of concrete since they occupy about 70 to 75% of the total volume of the concrete. It is logical to use maximum of aggregate, since they provide bulk to the concrete, are less expensive than cement and are freely available in nature.