Raymond Mill,Raymond Mill Working Principle

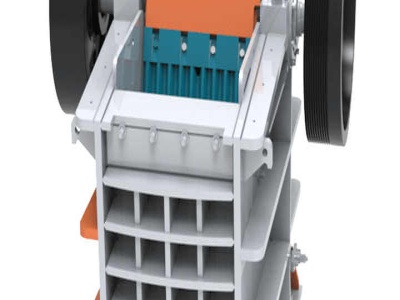

The whole working process of Raymond Mill (the process of grinding material): the bulk materials by jaw crusher to desired size, by the elevator will be material to the hopper, the vibrating feeder evenly and quantitatively and continuously into the indoor host grinding .