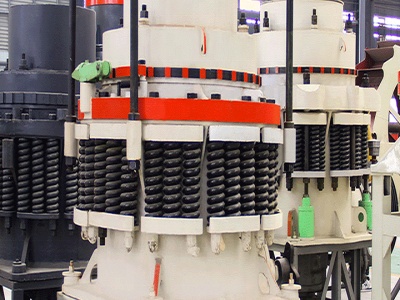

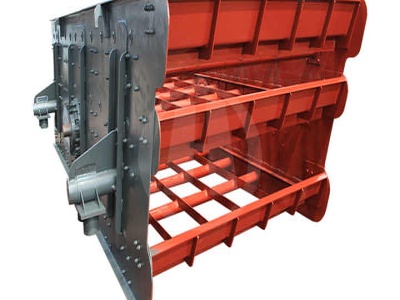

used grinding mill for gold ores grinding process

Grinding in Ball Mills: Modeling and Process Control, Ball mills, grinding circuit, process control, Typical examples are the various ores. Live Chat grinding copper ore process in australia ,