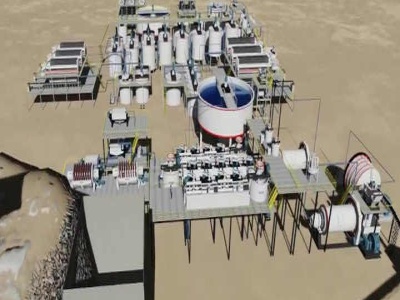

step for extracting iron ore

Iron Extraction Process. Iron Extraction Process. In the blast furnace process, the first step on the way towards heavy plate, pig iron is produced from iron ore. ... how to extract iron from the iron ore, extract iron in an iron furnace, examples and step by step demonstration, iron oxide, coke, limestone, slag, steel. Get Price Extraction Of ...