Flow sheet for pyrometallurgical extraction of copper from ...

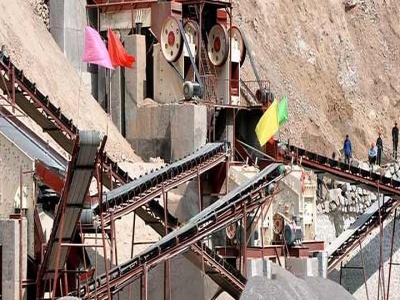

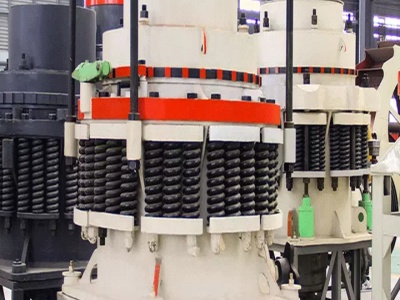

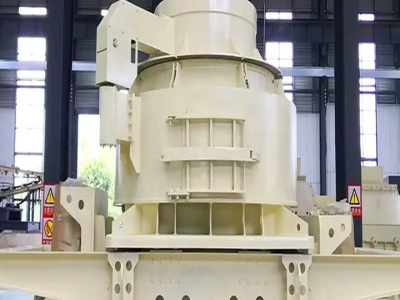

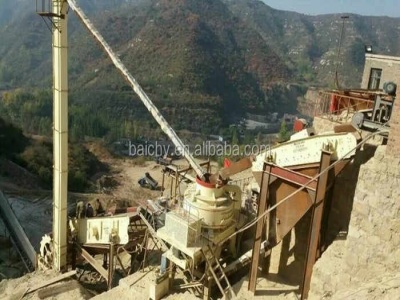

Flow sheet for pyrometallurgical extraction of copper from cu2s concentrate Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Flow sheet for pyrometallurgical extraction of copper from cu2s concentrate, quarry, aggregate, and different kinds of minerals.