Hot rolling B2 matrial SAG mill grinding balls for Cement ...

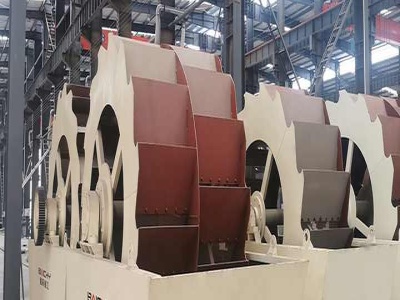

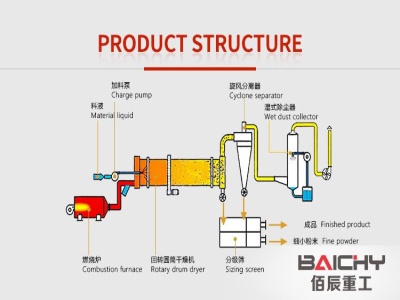

Hot rolling B2 matrial SAG mill grinding balls for Cement Plant . Quality guarantee . PRODUCT DETAILS G mill grinding balls commonly used lowcarbon alloy, high manganese steel,High Chrome steel.. To ensure the good quality,stable hardness,low breakage rate, Jinan zhongwei order all the raw material from national large steel millLaiwu steel group. SAG mill grinding balls Production Line