grinding flotation crushing

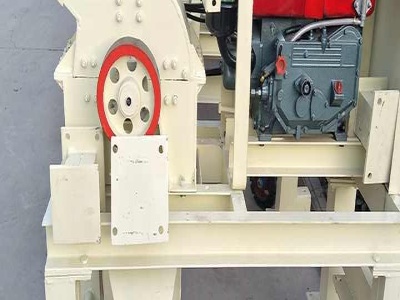

complete stone crushing and beneficiation plants. Mobile Cone Crusher. Mobile cone crusher station is mainly used in the field of crushing operations in aggregates production operations, depending on the use of stone and finished products, mobile cone crusher crusher station instead, producing higher hardness and more fine grained sand and gravel products.