manufacture of portland cement ppt

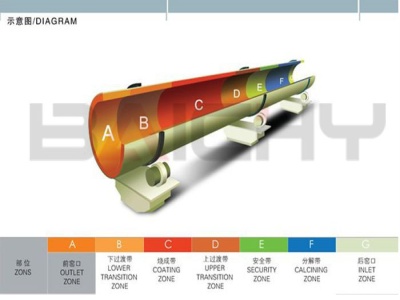

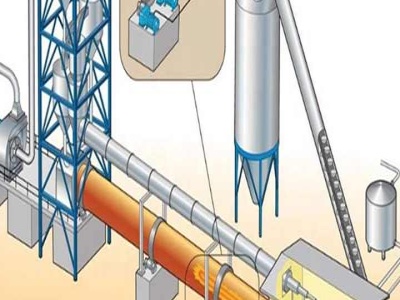

manufacture of portland cement ppt manufacture of portland cement ppt Portland Cement Drywall Recycling Market: Portland Cement Manufacture Gypsum is an ingredient in the manufacture of portland cement, added to control the Get Price And Support Online portland cement manufacturing process power point .