CEMENT CONCRETE AIA Automation

Cement: Control Strategy definition Computer Process Simulation for the Coke feeding system to the four Cement Kilns. 1993: CEMEXTorreón: Cement: Control Strategy Definition to eliminate perturbations in the Weighing Bin control of the feeding system to the cement kilns. GEFanuc PLC.

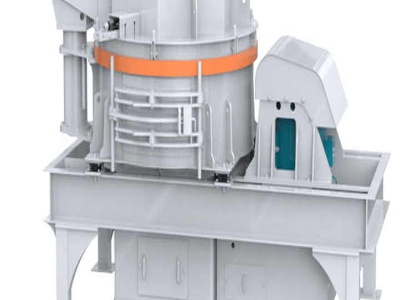

![The rotary cement kiln (Book, 1986) []](/dbi3hzc/241.jpg)

![The rotary cement kiln (Book, 1986) []](/dbi3hzc/1462.jpg)