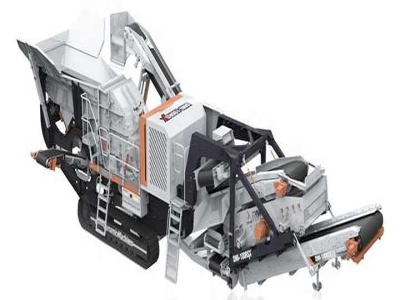

Edison and Ore Refining Engineering and Technology ...

Iron ore rock crushers used in Edison's iron ore refining business In 1892, Edison shut down the mill in the hopes that replacing some of the equipment would improve production. He made changes to the orecrushing machinery, installing huge rollers capable of turning out much larger quantities of ore.