cement mill power calculation

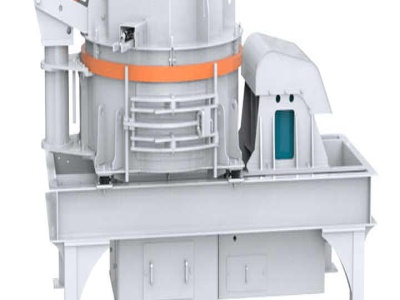

vertical roller mill in cement industry calculation. vertical roller mill in cement industry calculation. Vertical roller mill is a kind of energyefficient grinding machines, which is widely used in many fields such as producing raw and clinker material, grinding slag, ore, industrial silicon, calcium carbide residue, coal gangue in the cement industry and desulphurization process in the ...