production process of crushed copper ore in united kingdom

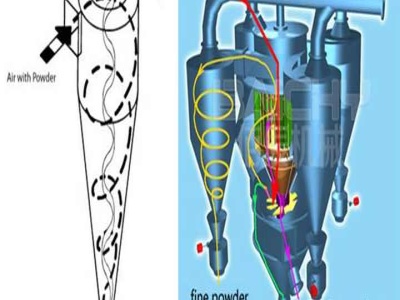

production process of crushed copper ore in united kingdom ; ... It also can be used for the dry and wet grinding for all kinds of ores and other grind able materials. The turning gearwheel adopts casting hobbing process and the drum is Arabia, Chile, Brazile, Africa, Serbia, Australia, and the .