Raymond Mill,Raymond Roller Mill,Raymond Grinding Mill ...

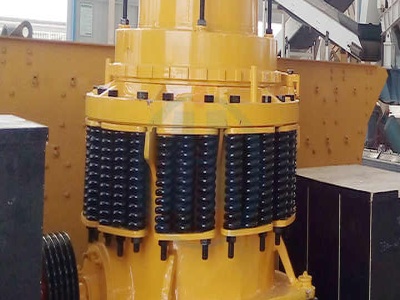

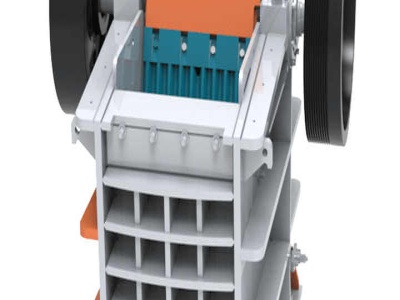

with the ball mill, the Raymond mill has higher efficiency, lower power consumption, smaller covered area, less investment. grinding roller compressed on the grinding ring tightly due to the centrifugal force. output and fineness of the finished product will not be affected when the grinding ring is worn to a certain degree.