EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL .

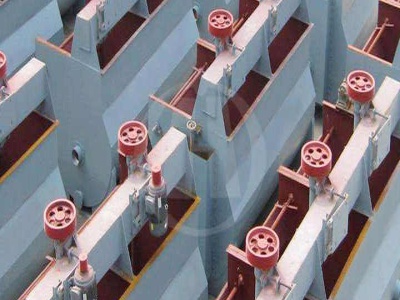

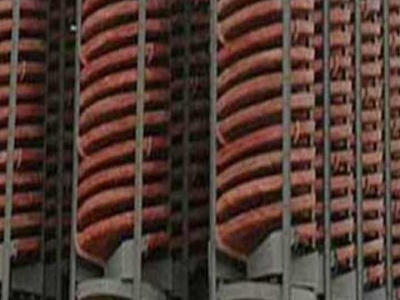

Considering tumbling ball milling; the variation of fraction of mill filled with balls. and powder, mill diameter, mill speed, media size and shape, ball density, ore type, and feed particle size distribution, as well as material properties affects the rate of. breakage and overall mill performance.