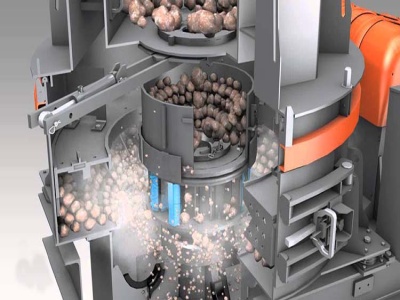

allmineral allflux®

Process control is automatic. The allflux ® has a throughput capacity of up to 2,000 cubic meters per hour. A top size of up to four millimeters can be easily processed. The advantages of the allflux ® have won recognition worldwide: sorting, separating, thickening and cleaning in one single step – .