Dry Cement Process

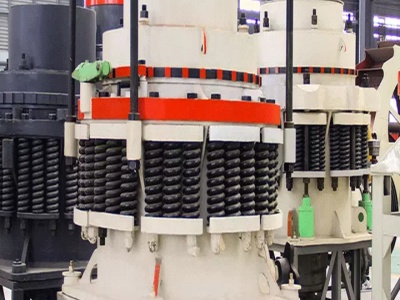

Which cement manufacturing method is best, wet or dry. If we consider the Quality and Rate then wet process is better and if we consider Fuel consumption and Time of Process then dry process is better.. Dry Process; The both calcareous and argillaceous raw materials are firstly crushed in the gyratory crushers to get 25cm size pieces separately.