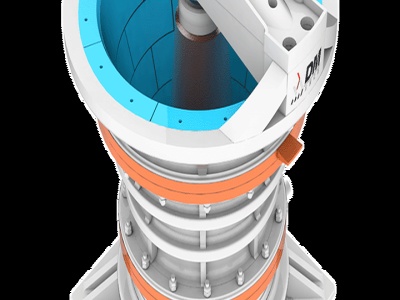

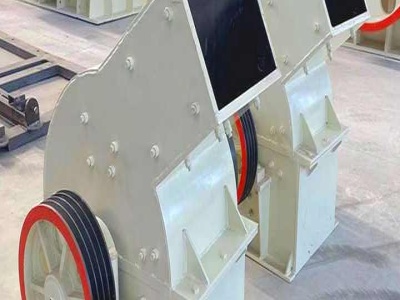

Crusher Equipment Solutions

principles of Ball Mill Operation; kothmale grinding mills; sewa hammer roller mill; current owners of crushers; coal crushers in vijayawada; operation of ball mill has believed; autogeneous grinding of iron ore; canciones i mill always love you de whitney housten; rock /clay crushing equipment; walter grinding machine; cane crusher china ...