Cement KIMA Process Control

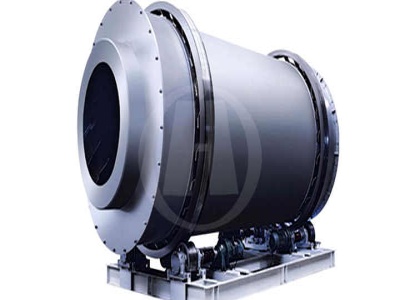

LEADING TECHNOLOGY IN BALL MILL CONTROL. With MillMaster KIMA Process Control offers the most robust, open and easy to handle Advanced Control System in the Cement Industry. Since 1996 this 'AutoPilot' system was installed in hundreds of cement plants to operate mills fully autonomously.