MM 400 Ball mill / nucleic acid extraction / for cell ...

Find out all of the information about the RETSCH product: ball mill / nucleic acid extraction / for cell disruption / with mixer MM 400. Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale.

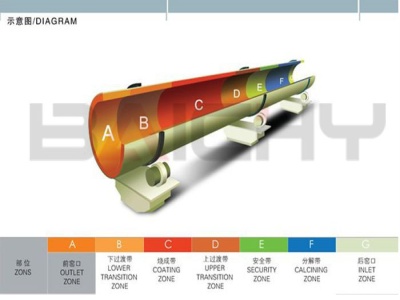

![Planetary Ball Mill specification[1]](/dbi3hzc/624.jpg)

![Planetary Ball Mill specification[1]](/dbi3hzc/1476.jpg)