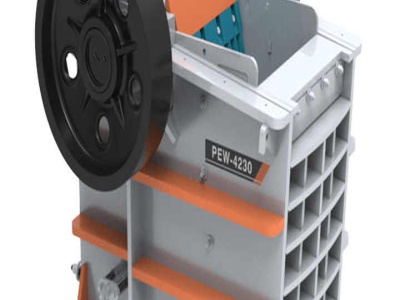

high capacity low energy cement clinker grinder price

High Capacity Cement Ball Mill Heavy Mining Machinery. The Cement Ball Mills on a cement plant are usually sized for clinker consumption, Low Price High Capacity Ball, Ball mill grinder is mainly . low capacity clinker grinder shribalajipropertiin