Red Dog Operations Teck

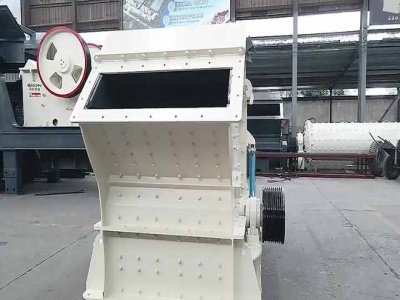

Late 1992: Installation of Ball Mill 1 and Ball Mill 2, which increased throughput. : Installation of additional Pb and Zn columns, which improved Pb and Zn recoveries. 1997: Commissioning of "Production Rate Increase", PRI, including SAG Mill 3, Ball Mill 4, some Zn flotation capacity, new reagent building, and the gyratory crusher