Calcium Carbonate Powder Vertical Roller Grinding Mill ...

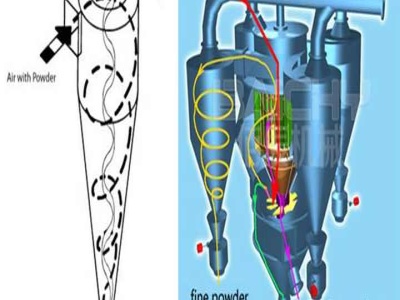

Calcium Carbonate Powder Vertical Roller Grinding Mill is suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under (the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite,