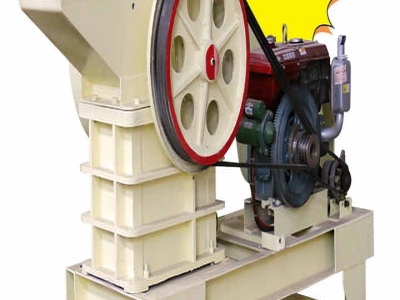

Ball Mill (Batch Type), बॉल मिल Tridev Industries ...

We have emerged in manufacturing and supplying a vast collection of Ball Mill (Batch Type) Grinding Mill which operates as a combination of operations like in batch. The offered products are used to grind wet or dry powder, so that they can be mixed with more .