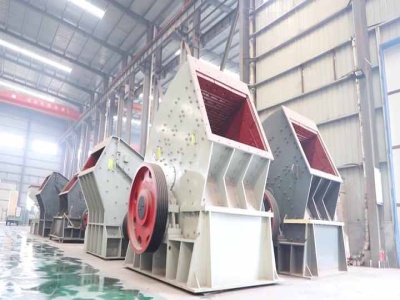

mineral processing geological grinding

mineral grinding Stand Up India. pattern data may be available from the respective state Geology Mining dept. In . Mineral grinding is a simple process and not much technical complexity. Contact US Determination of Bond index of Birnin Gwari Iron Ore in Nigeria. Bond index is useful in designing of grinding system in mineral processing.