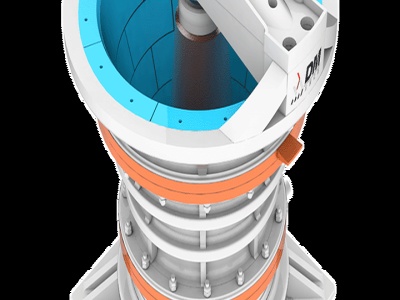

blast furnace flow chart

blast furnace | metallurgy | Jan 28, 2016 ... A vertical shaft furnace that produces liquid metals by the reaction of a flow of air introduced under pressure into the bottom of the furnace with a... More details » Get Price. Blast Furnace and Stoves Eurotherm.