EVALUATION OF ORGANIC CARBON SEPARATION FROM .

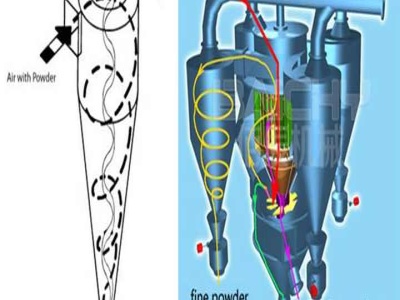

The idea behind the process is channeling the material, after grinding and classifi cation in hydrocyclones, to preflotation, which results in two products: rich in organic carbon concentrate and poor in carbon waste material, which is the feed for further concentration processes.