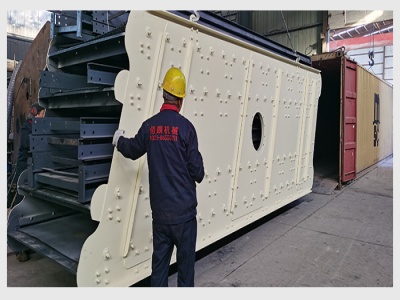

Industrial Grinding Wheels | Products Suppliers ...

. the possibility of manufacturing a substrate for grinding wheels suitable for high speed and ultrahighspeed At present, notable research and application achievements in the design, manufacture, experimentation, and industrial application of grinding wheels with a CFRP substrate .